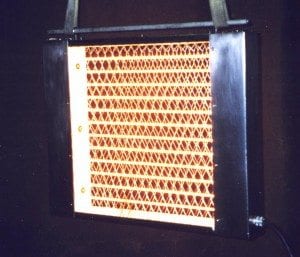

Infrared Die Pre-Heaters

The Infrared Die Pre-Heater™ offers better performance at less cost than a conventional die heater.

Long life T3 radiant heating elements for fast, efficient, uniform, and clean heating.

Stainless steel construction with TIG welded seams make the unit industrially robust.

Expanded metal stainless steel guard to protect elements.

Stainless steel electrical enclosure pre-wired for simple plug-in installation. No controls necessary.

Eliminate scrap at start-up, maintain die heat during production breaks, reduce die maintenance, and increase die life

- FAST The Infrared Die Pre-Heater’s™ high efficiency and high burn temperature lead to much faster heat-up than gas burners or standard electric element heaters. Typical pre-heat times are less than one hour.

- EFFICIENT T3 radiant heating filaments convert electricity into infrared radiant heat at approximately 90% efficiency, nearly twice the efficiency of standard electric die heaters.

- CLEAN Electric infrared heating is clean without any combustion by-products which must be removed from the die surface.

- UNIFORM The uniform heat density of the Infrared Die Pre-Heater™ leads to extremely even die temperatures.

- SIMPLE TO OPERATE Simply place the unit between the die opening and plug it in. No controls are required.

- LOW COST The long element life (in excess of 5,000 hrs), efficient heating, and low element replacement costs make the Infrared Die

Infrared Heating Technologies’ Die Pre-Heater’s™ employ a high intensity, short wave, tungsten filament to transfer heat to the part. This filament has several advantages over conventional heaters including faster heat-up with less power consumption than standard electric or gas heaters.

52.5 KW Die Pre-HeaterTM designed and manufactured for large forge company. Features 0-100% manual and PID/Fuzzy Logic automatic temperature control modes for precise control of die temperature.

52.5 KW Die Pre-HeaterTM designed and manufactured for large forge company. Features 0-100% manual and PID/Fuzzy Logic automatic temperature control modes for precise control of die temperature.

18 KW Die Pre-Heater™ designed and manufactured for forge company. Features PID/Fuzzy Logic automatic temperature control, positioning handles, and hinged heat reflector shields.

Custom design and manufacturing is our specialty. Let us build an Infrared Die Heater specifically designed for your application without the high cost and long turn around time found with most custom products.

Originally introduced to the die cast industry as a better tool for pre-heating die while inside the die cast machine, the Infrared Die Pre-Heater™ is proving to be a better tool for pre-heating tooling inside hammer forges. In recent demonstrations at a large forge shop, the Infrared Die Pre-Heater™ heated the tooling inside a large hammer forge to 600oF in less than 30 minutes. This compares quite favorably to the several hours of pre-heat required of conventional heating techniques.