Call Us Today! 1-865-535-0050 | info@infraredheating.com

Gas Infrared Ovens

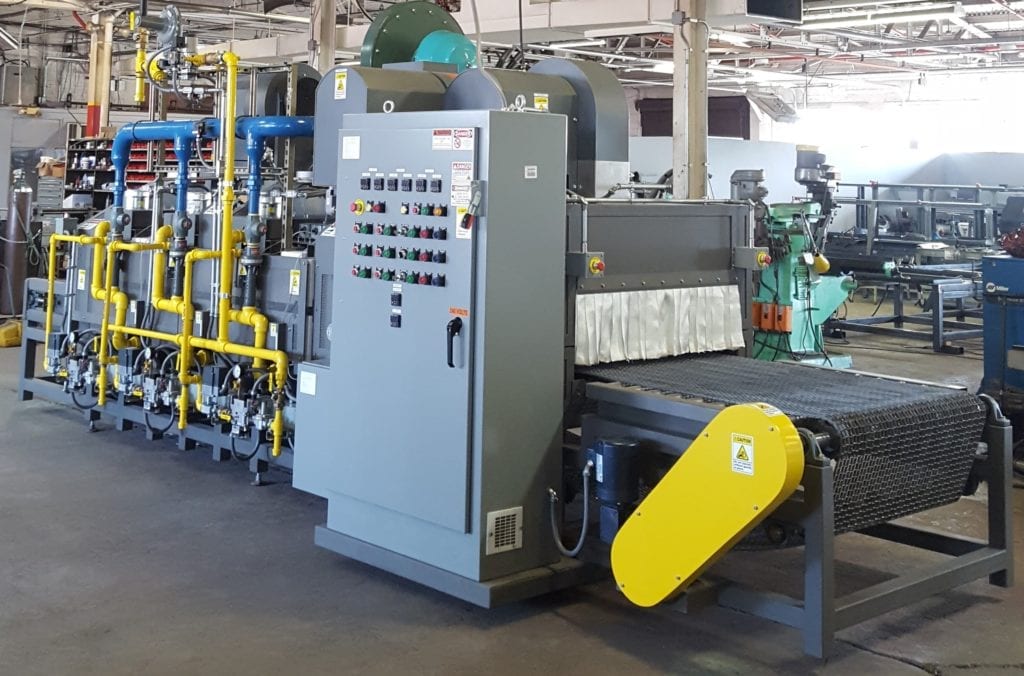

Gas Infrared Ovens employ direct fire natural gas emitters for a combination of long wave infrared radiation and convection heating. Pictured below is an Infrared Heating Technologies gas infrared chain conveyor oven designed and manufactured for a stone tile drying process. These ovens have extremely high throughputs and low operating costs.

Also pictured is a Natural Gas Fired Infrared Conveyor Belt Furnace, Cooler, and Controls System for a major manufacturer of furniture and bedding springs.

This furnace system includes three (3) heat temperature control zones, each incorporating top and bottom, (above the belt and below the belt), Maxon RadMax premix gas-fired infrared burners. These burners are implemented into the furnace structure using our proprietary design for reducing the heater panel manifold temperatures, while still maintaining the full burn temperature of the gas fired heater panel surface for maximum efficiency and heater longevity.

Direct Fired Natural Gas Infrared Tunnel Oven and Controls System for a major manufacturer of metal building systems.

Infrared Heating Technologies, Inc

2010 HWY 58, Suite 2120 Oak Ridge, TN 37830

Phone: 1-865-535-0050

Email:info@infraredheating.com

Copyright © 2015-17. Infrared Heating Technologies, LLC.